- #Download analytics problem solver for excel software

- #Download analytics problem solver for excel trial

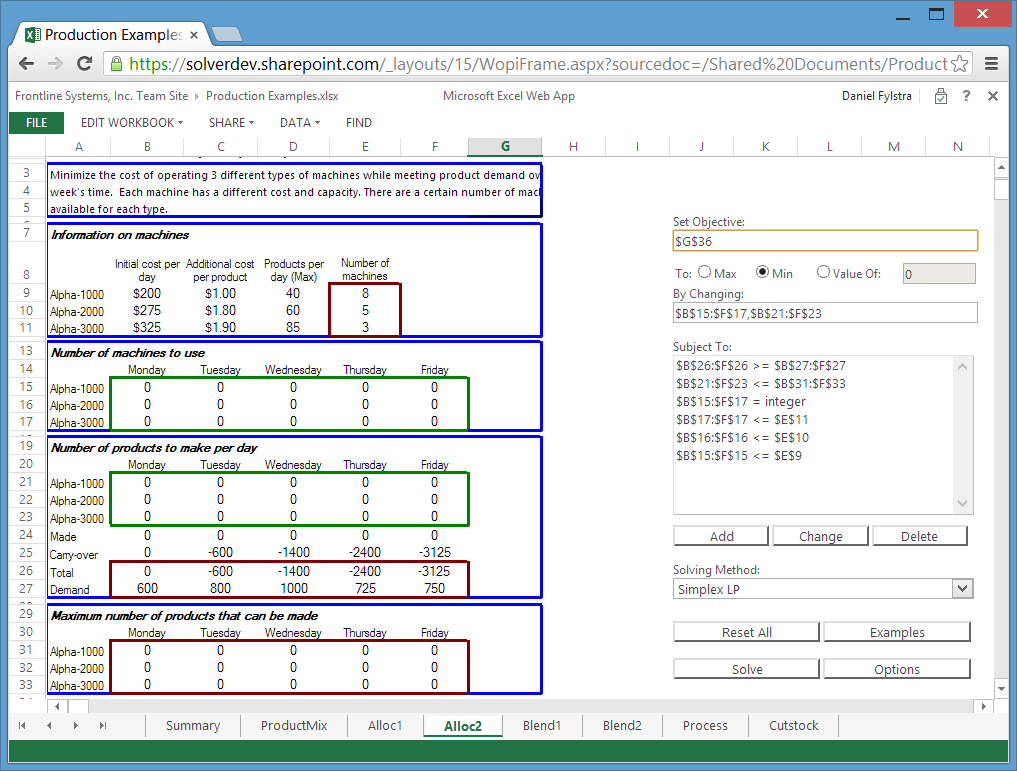

In our example, we suppose that one large truck has a maximum carry volume of 110 units. To know how many trucks we need to deliver the quantity incurred from one DC to a Store, we have to divide this quantity by the maximum carry volume of our trucks and round that number up ( The ROUNDUP Function in Excel ). In our case, we only have the cost per Km traveled, and so we will use the first option. If we have the cost per Km per unit, then the total cost will be equal to the cost per km per unit, multiplied by the distance of each route, and then multiplied by the number of units sent on those routes.The total transportation cost can be equal to the cost per Km multiplied by the distance of each route and then multiplied by the number of deliveries needed since vehicles have a maximum carry volume.We did that so we can add quickly and easily the capacity constraint in Solver.ī efore creating and running our solver model, we should define the total cost formula. We also copied the DC’s and capacity matrix, and we pasted its Transpose. The values on the right side of the matrix are the total quantity delivered to each store, and the values below the matrix are the total quantity that each DC will transfer. We can make the value in the yellow matrix zeros, but to make sure that our rows and columns sums are correct, we made them equal to one. The decision variables that will be changing are colored in yellow. Therefore, the changing variables in our case are the number of units moving on each route. Remember, our goal is to find delivery quantities from DCs to stores that minimize transportation costs while still meeting store demand. Next, create the changing variables in your spreadsheet template.

This default value may be modified to accurately reflect current actual costs per Km based on your research.

#Download analytics problem solver for excel software

The cost per Km is $ 0.60 which is a default value in the software for large trucks. These are round trip distances provided by the SCM Globe software. The second step is to enter the distances between all sources and destinations. We can easily see we have enough capacity to cover market demand. That gives us a total capacity of 2100 units. Then enter the unit storage capacity for each distribution center. Start by entering each store’s demand that gives us a total demand of 1190 units in this case. The first step in our process is to enter the data we need from the supply chain model in an organized manner. Now that we have defined the problem and the network model, it’s time to move to Excel to enter the data and make our analysis. Shown below is an abstract network design diagram for the supply chain model in the screenshot above: Moving to Excel

#Download analytics problem solver for excel trial

We are glad to provide a free evaluation account to instructors, students and supply chain professionals interested in exploring SCM Globe simulations - click here to request an account - Get Your Free Trial Demo The screenshot below shows this network of facilities. Facilities are put on the map using the SCM Globe supply chain modeling and simulation app. It’s a simple network with two stages: three Distribution Centers and the other eight facilities are Stores.

0 kommentar(er)

0 kommentar(er)